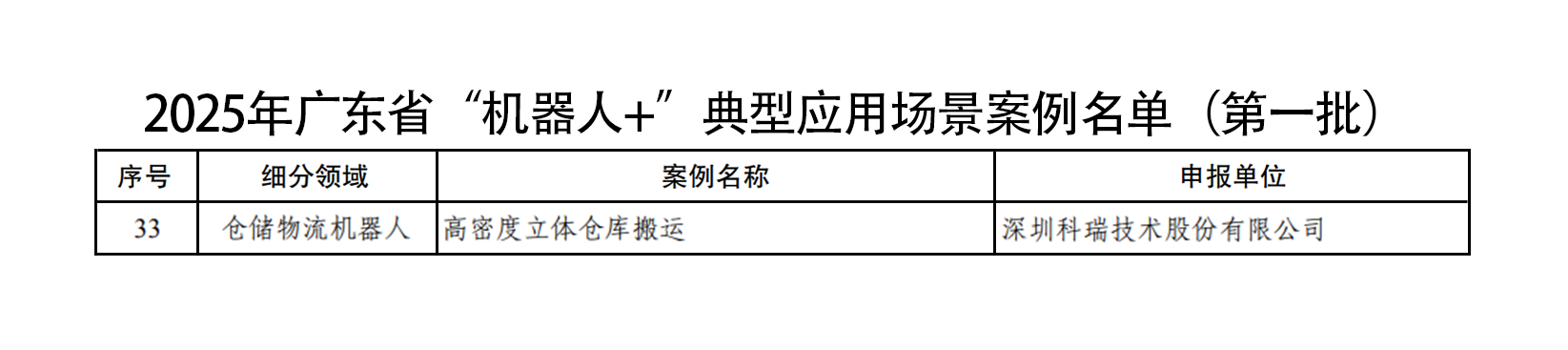

Recently, the Office of Guangdong

Provincial Leading Group for Innovation and Development of Artificial

Intelligence and Robot Industry announced the first batch of the 2025 "Robot+"

typical application scenarios. Colibri Technologies successfully made the list

with its "High-Density Automated Warehouse Handling Robot+" solution,

becoming a benchmark case in the field of warehousing and logistics robotics.

This achievement highlights Colibri Technologies' leading capabilities in the

intelligent logistics sector.

Breaking

the Pain Points of Traditional Warehousing and Reshaping Logistics Efficiency

Against the backdrop of e-commerce growth

and manufacturing supply chain upgrades, the shortcomings of traditional

high-density storage stereoscopic warehouses have become increasingly prominent

— low efficiency, high costs, and high error rates. Manual picking struggles to

handle massive SKUs, while issues such as insufficient space utilization and

poor equipment coordination have severely restricted warehousing capabilities.

Colibri Technologies has introduced an

AI-powered intelligent logistics robot system for high-density automated

warehouses. By integrating AGVs, suction-cup robotic arms, 3D vision, and AI

algorithms, the company has developed an efficient, precise, and flexible

warehouse automation solution.

Equipped with 3D machine vision, the robots

can accurately identify containers and cargo features, while AI algorithms

autonomously plan optimal paths, allowing for agile navigation in narrow

aisles. The suction-cup robotic arms can adjust gripping force to stably handle

containers of different materials and shapes. The lift mechanism, working in

tandem with the retrieval robots, can reach storage locations up to 6 meters

high, significantly improving warehouse space utilization.

The system achieves multiple technological

breakthroughs:

Intelligent Scheduling: AI algorithms optimize robot routes and task allocation in real

time, minimizing unnecessary movement.

Perception:

LiDAR and vision sensors work together to detect obstacles, ensuring

operational safety.

Data Management: The system logs cargo volumes and adjusts storage locations based

on historical picking frequency, placing high-demand goods on lower levels to

enhance picking efficiency.

Continuous

Innovation Driving Industry Advancement

Colibri Technologies remains committed to

advancing the industry through technological innovation. By refining AI

algorithms, the company enhances robots' ability to recognize and handle

complex environments and irregularly shaped goods. It is also developing

high-efficiency power systems to extend robot operation time and exploring

deeper integration of 5G, IoT, and other technologies with robotic systems.

Additionally, Colibri Technologies strengthens collaboration with universities

and research institutions to conduct cutting-edge research in autonomous

navigation and multi-robot cooperative swarm operations.

With 24 years of professional expertise in

automation equipment R&D and manufacturing, Colibri Technologies has

established four core business segments in the smart logistics sector:

intelligent distribution, conveying and sorting, automated warehousing, and

smart factories. Leveraging these core capabilities, the company provides

end-to-end smart logistics solutions covering the entire production process,

enabling fully automated material handling and intelligent scheduling

management—from raw material storage to finished product dispatch.

Currently, through its mature global

delivery system, Colibri Technologies has successfully deployed smart logistics

solutions in overseas markets such as Thailand and Indonesia. Looking ahead,

the company will continue to deepen technological innovation and market

expansion in smart logistics, driving the industry toward sustained

advancements in intelligence and automation.