On November 28th, Chinese Premier Li Qiang attended the opening ceremony of the first China International Supply Chain Expo and the Global Supply Chain Innovation and Development Forum, and delivered a keynote speech in Beijing on Tuesday.

The China International Supply Chain Expo (CISCE for short), the world's first national-level supply chain expo, providing a platform for global enterprises to engage in trade promotion, investment cooperation and learning amid global economic challenges.

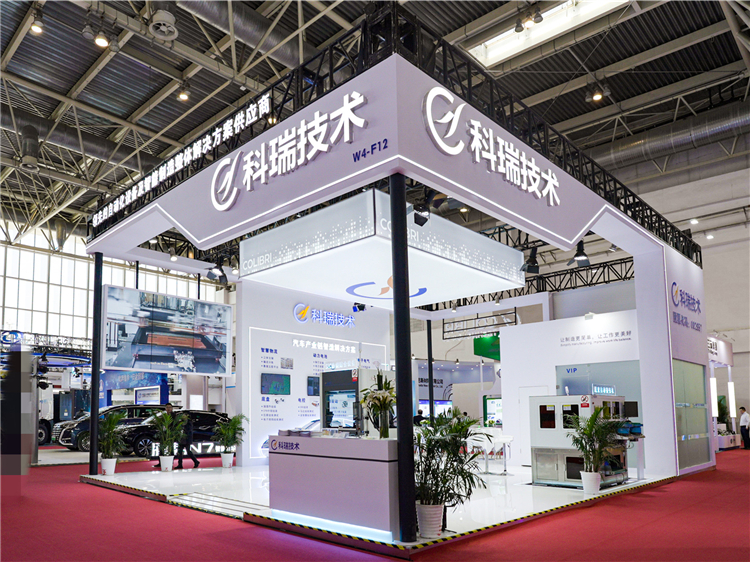

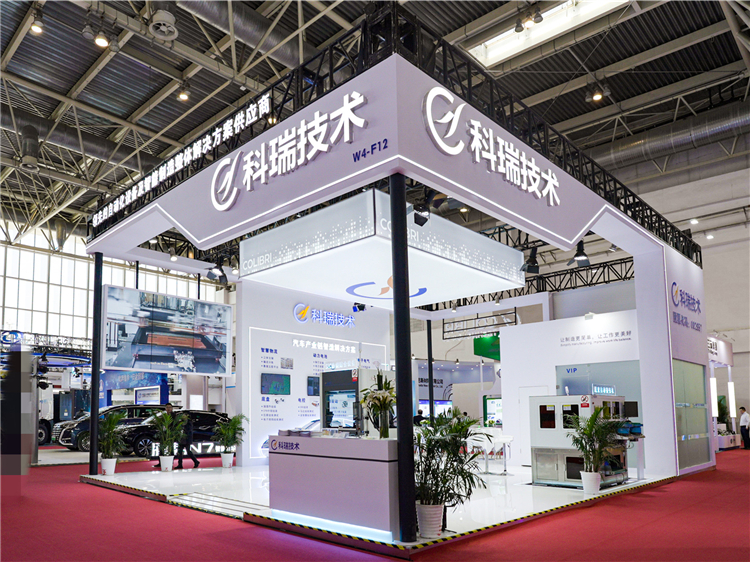

As a leading domestic automation equipment & intelligent manufacturing solutions enterprise, Colibri Technologies has been committed to lead intelligent manufacturing solutions for optimizing production efficiency through innovative automation technologies. As an essential part of production manufacturing, the industrial automation equipment produced by Colibri Technologies can effectively improve customers’ production efficiency, product quality, and level of production intelligence, helping customers achieve industrial automation production with new processes and technologies. Through the platform of the CISCE, we hope to fully demonstrate our equipment manufacturing capabilities, deeply integrate into the global industrial supply chain system, and collaborate with industry counterparts upstream and downstream, and become an indispensable part of the world’s industrial supply chain system.

At the first CISCE, Colibri Technologies has highlighted its automotive industry chain solutions. The showcased solutions cover the entire industry chain of intelligent manufacturing production, including modules such as intelligent driving, electric drive, electronic and electrical components, electronic control, and power batteries in the automotive industry. The products span across all forms of industrial automation process, including components, molds, clamping fixtures, standalone equipment, complex assemblies, and automated production lines.

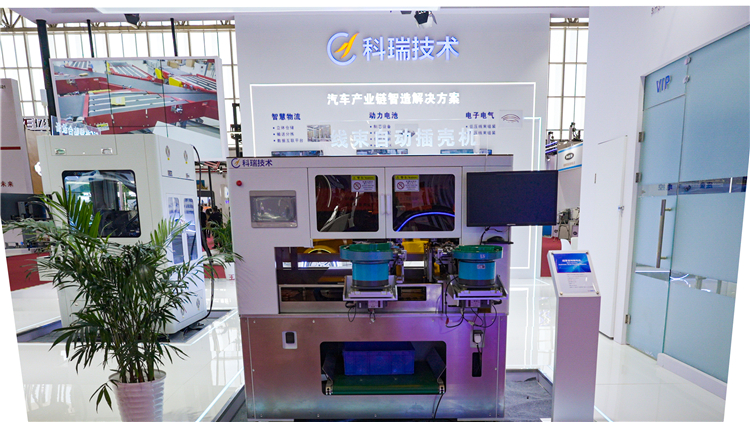

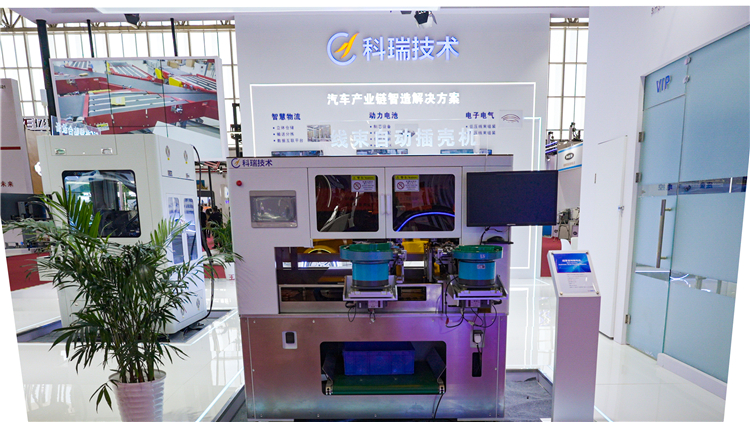

The typical equipment applications prominently showcased include an automatic wire harness crimping machine for automotive electronic and electrical systems and a SiC hot bonding equipment for drive systems.

The wire harness crimping machine is primarily used for processing low-voltage wire harnesses inside household appliances and equipment, with automatic adjustment of wire harness length. It integrates cutting, stripping, terminal pressing, and shell insertion, with online visual inspection to ensure product quality. One machine can replace more than 10 manual workers, achieving a UPH of up to 1800 wire harnesses and accommodating wire harness lengths ranging from 80 to 1300mm. It breaks through the barriers of imported equipment and ensures supply chain stability.

The SiC hot bonding equipment is utilized for SiC hot bonding assembly, enabling the thermal pressing assembly of various specifications of products. It achieves mounting accuracy within ±10μm, temperature control precision within ±2℃, and force control accuracy within ±1N, thus capable of replacing imported equipment of the same specifications domestically.